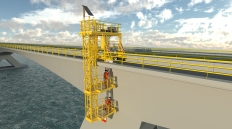

hosetower gangway hosereels

-

hosetower gangway hosereels

Engicon N.V (Geldof)

-

Mobile Cementing Unit

COVRA

-

scaffold for the Zeelandbrug

Provincie Zeeland (The Province of Zeeland)

-

Control system Head impactor

SABIC, Bergen op Zoom

-

Hose tower Bitung, Indonesia

Usaha Jayamas Bhakti, Jakarta

-

Replacement filling machine

Molenaar Betonindustrie

-

Climate box Element Material BV

Element Materials B.V.

-

Hose tower Sierra Leone

Bam Leidingen & Industrie

-

Transformer Substation 1250kVA

Vesta Terminal Flushing B.V.

-

ICT/TV Processing Line

Sims Recycling Solutions

-

E&I Installation Tank Terminal

Vesta Terminal Flushing B.V.

-

Chemical metering station

COVRA N.V.

-

Crate tilting device

Sims Recycling Solutions

-

Container Tilting Installation

Sims Recycling Solutions

-

Hose tower Flushing

Vesta Terminal Flushing B.V.

-

Barrel Emptying System

COVRA N.V.

-

Hose Towers for BTT

Naftobudowa SA

-

Stainless Steel Vessels and Tran

NRG and COVRA

-

LCD processing line Sims

Sims Recycling Solutions

Project information

Project description:

LBC Rotterdam is located right in the petrochemical heart of the largest port in Europe. The storage tanks and related infrastructure can handle almost all (chemical) liquids. It can accommodate different transport modes via water, road and rail. In addition to storage, the site offers blending, formulating, IBC filling, drumming, packaging and warehousing services.

For Engicon N.V. the project included among others the realization of 16 new storage tanks. Engicon N.V will not only build and supply the 16 tanks but also the superstructure of the jetty, pipes, storage tanks and related infrastructure.

Engicon N.V. has given Delmeco Projecten the order for the design and build of 2 new hose towers (total of 27+9 product lines), a gangway, 5 vapor return hose reels and 3 nitrogen hose reels. All the parts are built on the new Jetty.

Delmeco’s hose tower is built to maneuver hoses on the ships for the loading and unloading. The load can consist of various chemicals.

The hosereel installation will give ships the possibility to de-gas during the loading and un-loading. At the same time nitrogen can be supplied.

Furthermore, the gangway provides easy access to the docking ships while also serving as a escape route in the event of calamities.

The order required mechanical engineering, electrical engineering and automation for the following:

- The customer-specific design, engineering and drawing of the hose towers (including the 36 product lines), the gangway, the vapor return hose reels. The nitrogen hose reels for the vapor return and nitrogen hose reels required the build of a support structure including a platform that was included in the order.

- The construction of the installation pre-fab at Delmeco. The installation consisted of;

- 3 skid frames for the hose towers;

- 3 hydraulic knuckle boom cranes with a reach of 15,5 meter including a ATEX certified winch and hydraulic unit ;

- 36 hydraulic sliding beams with a reach of 4 meters;

- 3 control cabinets;

- 27 8” and 9” hoses including hose-bun/hose-sling for the loading of chemicals;

- 5 vapor retour hose-reels 4” with hoselength of 30 meters. Suitable for ATEX zone 1;

- 3 nitrogen hose-reels 3” with a hose length of 30 meters. Suitable for ATEX zone;

- 2 times a platform with supporting construction for the hose reels;

- 1 gangway to provide access from the jetty to the docking ships. Vertical reach approximately 12,5m. Rotation angle approximately 25⁰ until 95⁰;

- 4 radiographically controlled remotes for the control of the hose towers, hose reels and the gangway.

- All the relevant components are EExd (pressure resistant) or EExi (intrinsically safe).

- The execution of a FAT (Factory Acceptance Test) at Delmeco.

- The transportation of the complete installation to LBC Rotterdam.

- The assembly, connecting and commissioning of the complete installation on the new jetty.

- Perform the SAT (Site Acceptance Test) on location.

- Provide training for the operators and technical staff of LBC.

Client: Engicon N.V (Geldof)

Engicon N.V. (Geldof), Harelbeke, Belgium, is a leading European supplier of ‘integrated steel solutions’ for the storage, handling and processing of bulk liquids, solids and gasses.