Hose tower Flushing

-

hosetower gangway hosereels

Engicon N.V (Geldof)

-

Mobile Cementing Unit

COVRA

-

scaffold for the Zeelandbrug

Provincie Zeeland (The Province of Zeeland)

-

Control system Head impactor

SABIC, Bergen op Zoom

-

Hose tower Bitung, Indonesia

Usaha Jayamas Bhakti, Jakarta

-

Replacement filling machine

Molenaar Betonindustrie

-

Climate box Element Material BV

Element Materials B.V.

-

Hose tower Sierra Leone

Bam Leidingen & Industrie

-

Transformer Substation 1250kVA

Vesta Terminal Flushing B.V.

-

ICT/TV Processing Line

Sims Recycling Solutions

-

E&I Installation Tank Terminal

Vesta Terminal Flushing B.V.

-

Chemical metering station

COVRA N.V.

-

Crate tilting device

Sims Recycling Solutions

-

Container Tilting Installation

Sims Recycling Solutions

-

Hose tower Flushing

Vesta Terminal Flushing B.V.

-

Barrel Emptying System

COVRA N.V.

-

Hose Towers for BTT

Naftobudowa SA

-

Stainless Steel Vessels and Tran

NRG and COVRA

-

LCD processing line Sims

Sims Recycling Solutions

Project information

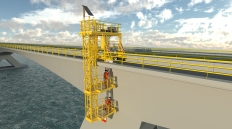

Project description:

When liquids are transferred to and from ships, hoses are used to make the connection between the ship and the installation close to the terminal. In order to handle them properly, a hose tower is used. Delmeco designed, provided and installed a hose tower for Vesta Terminal Flushing B.V. for the handling of hoses.

The assignment comprised:

- The prefab construction of the hose tower (after execution of the engineering within Delmeco Raadgevend Ingenieursbureau).

- The installation mainly consists of:

-

- A nautical telescope crane;

- 4 hydraulic winches, 8 hosebuns (hose guide) and 4 12-metre-long 10” hoses;

- A support construction incl. platform and guard;

- A drip can construction for catching any residual liquids from the hoses;

- A waiting room for operators;

- A hydraulic and electrical installation incl. radiographic control;

- A fire fighting system incl. nozzles.

- Constructing the control panel;

- Installing (E and W) on location at Vesta, Vlissingen;

- Running a SAT (Site Acceptance Test) on location at Vesta.

For this project, it was Delmeco’s responsibility to complete the hose tower and deliver it turn-key and operating.

For more information you can also visit our website: hosetowers.com

Client: Vesta Terminal Flushing B.V.

Vesta Terminal Flushing B.V. (VTF) is a tank terminal with three locations in Vlissingen. Vesta’s main activity is the storage and transferral of a wide range of petroleum products and bio fuels. Vesta is a subdivision of the worldwide Mercuria Energy Group.