Laagwerkers Zeelandbrug

Provincie Zeeland

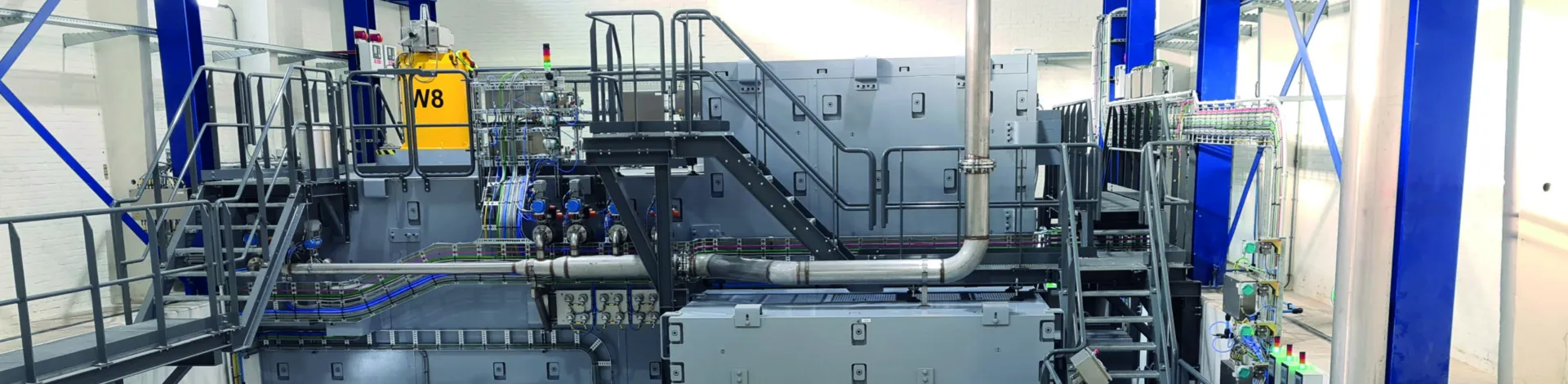

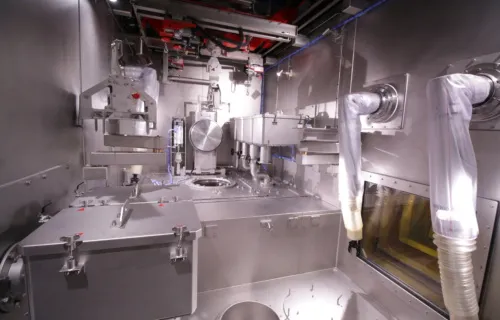

Delmeco Projecten werkt voor uiteenlopende opdrachtgevers zowel nationaal als internationaal, in sectoren zoals de nucleaire industrie, (petro)chemie, voedingsmiddelenindustrie en de recycling-industrie. Door ons te richten op klantgerichte machinebouw en industriële installaties van engineering tot realisatie creëren we blijvende meerwaarde voor onze opdrachtgevers.

Elk project vertelt zijn eigen verhaal. Hieronder tonen we een selectie van gerealiseerde projecten, die laten zien waar technische kennis, samenwerking en vakmanschap toe leiden.

Provincie Zeeland

Diverse opdrachtgevers

Anthony Veder

Eagle LNG

NRG Petten

Vesta Terminal Flushing BV

Vesta Terminal Flushing BV

Sims Recycling Solutions

Sims Recycling Solutions

NRG en COVRA N.V.

COVRA N.V.

COVRA N.V.

Element Materials Technology B.V.

Vesta Terminal Flushing BV

COVRA N.V.