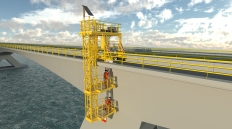

Hose Towers for BTT

-

hosetower gangway hosereels

Engicon N.V (Geldof)

-

Mobile Cementing Unit

COVRA

-

scaffold for the Zeelandbrug

Provincie Zeeland (The Province of Zeeland)

-

Control system Head impactor

SABIC, Bergen op Zoom

-

Hose tower Bitung, Indonesia

Usaha Jayamas Bhakti, Jakarta

-

Replacement filling machine

Molenaar Betonindustrie

-

Climate box Element Material BV

Element Materials B.V.

-

Hose tower Sierra Leone

Bam Leidingen & Industrie

-

Transformer Substation 1250kVA

Vesta Terminal Flushing B.V.

-

ICT/TV Processing Line

Sims Recycling Solutions

-

E&I Installation Tank Terminal

Vesta Terminal Flushing B.V.

-

Chemical metering station

COVRA N.V.

-

Crate tilting device

Sims Recycling Solutions

-

Container Tilting Installation

Sims Recycling Solutions

-

Hose tower Flushing

Vesta Terminal Flushing B.V.

-

Barrel Emptying System

COVRA N.V.

-

Hose Towers for BTT

Naftobudowa SA

-

Stainless Steel Vessels and Tran

NRG and COVRA

-

LCD processing line Sims

Sims Recycling Solutions

Project information

Project description:

Naftobudowa was commissioned by Botlek Tank Terminal to build the first phase of the new terminal of the Botlek Tank Terminal in Rotterdam.

Delmeco has designed, delivered and installed three hose towers for Naftobudowa, which are part of the first phase of the new BTT terminal. The hose towers serve to manoeuvre six (8”) hoses (three times) to and from a ship for loading and unloading cargo. This cargo may consist of various types of oils.

For the disciplines of mechanical engineering, electrotechnology and automation the commission consisted of:

- Design, engineering and drawing of the hose towers including the subframe;

- Prefab building of the three installations at Delmeco. Each installation primarily consists of:

- A hydraulic nautical telescopic crane with a 15.5 m range including hydraulic winch and hydraulic unit;

- 6 hydraulic sliding beams with a 5 meter range;

- 6 hydraulic winches;

- a control board designed in EExd, in conformity with the ATEX guidelines;

- Radio control of the crane and the winches. All relevant components are designed in EExd (explosion proof) or EExi (intrinsically safe).

- Performing a FAT (Factory Acceptance Test) at Delmeco;

- Transport to the BTT location in Rotterdam;

- Installing the installations on site;

- Performing a SAT (Site Acceptance Test).

For this project, Delmeco is responsible for the Turn-Key delivery of the hose towers for all subject disciplines from design to realisation.

For more information you can also visit our website hosetowers.com

Client: Naftobudowa SA

Naftobudowa is a part of Polimex Mostostal, one of Poland´s major employers. Naftobudowa´s main field of activity is delivery and assembly of tanks and industrial installations in, amongst others, the (petro)chemical industry.