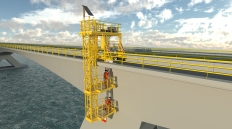

Hose tower Sierra Leone

-

hosetower gangway hosereels

Engicon N.V (Geldof)

-

Mobile Cementing Unit

COVRA

-

scaffold for the Zeelandbrug

Provincie Zeeland (The Province of Zeeland)

-

Control system Head impactor

SABIC, Bergen op Zoom

-

Hose tower Bitung, Indonesia

Usaha Jayamas Bhakti, Jakarta

-

Replacement filling machine

Molenaar Betonindustrie

-

Climate box Element Material BV

Element Materials B.V.

-

Hose tower Sierra Leone

Bam Leidingen & Industrie

-

Transformer Substation 1250kVA

Vesta Terminal Flushing B.V.

-

ICT/TV Processing Line

Sims Recycling Solutions

-

E&I Installation Tank Terminal

Vesta Terminal Flushing B.V.

-

Chemical metering station

COVRA N.V.

-

Crate tilting device

Sims Recycling Solutions

-

Container Tilting Installation

Sims Recycling Solutions

-

Hose tower Flushing

Vesta Terminal Flushing B.V.

-

Barrel Emptying System

COVRA N.V.

-

Hose Towers for BTT

Naftobudowa SA

-

Stainless Steel Vessels and Tran

NRG and COVRA

-

LCD processing line Sims

Sims Recycling Solutions

Project information

Project description:

BAM International / BAM Leidingen & Industrie was commissioned by Oryx Energies to engineer and build the petroleum jetty on the Kissy Oil Terminal of Freetown in Sierra Leone.

BAM Leidingen & Industrie commissioned Delmeco Projecten to design and build a new hose tower, which will be placed upon the new jetty. The hose tower serves to manoeuvre hoses to and from a ship for loading and unloading. The cargo generally consists of various types of oils and LPG.

For the subject disciplines engineering, electrical engineering and automation, this commission consisted of:

- Designing, engineering and drawing the hose tower with subframe and mainframe, the fire protection system, the piping and the electrical part.

- Prefab building of the installation at Delmeco. The installation consists in the main of:

- A mainframe and a subframe, inclusive of 2 ladder cages;

- A hydraulic nautical telescopic crane with a 15.5 metre range inclusive of ATEX certified hydraulic winch and hydraulic unit;

- 6 hydraulic sliding beams with a 5 metre range;

- 2 control panels;

- 1 hose 6” for LPG, including a breakaway coupling and dry break coupling;

- 5 hoses 10” for petroleum-based products, with hosebun/hose-ling;

- 1 loading platform for the fire-fighting system, including foam/water fire-monitor;

- Radio control for the crane and sliding-beams. All the relevant components are designed in EExd (explosion proof) or EExi (intrinsically safe).

- Performing a FAT (Factory Acceptance Test) at Delmeco;

- Preparing the installation for transport to Sierra Leone.

In Sierra Leone the hose tower will be mounted on the newly-built Jetty, which is 200 metre of the coast. Together with the customer, a SAT (Site Acceptance Test) will be performed. In addition, Delmeco gives training and instruction to the operational staff.

Within this project Delmeco is responsible for the Turn-Key delivery of the hose towers for all subject disciplines, from design to build.

For more information you can also visit our website: hosetowers.com

Client: Bam Leidingen & Industrie

As part of Koninklijke BAM Groep nv, BAM Leidingen & Industrie BV is a technical multidisciplinary service provider. Its core business is engineering, procurement, construction, project management, control and maintenance of aboveground and underground industrial installations.